Asphalt vs Concrete Driveway Material: Pave An Asphalt Driveway

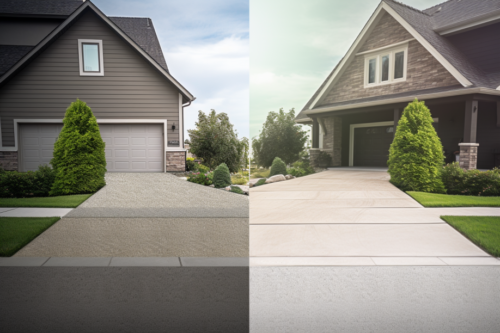

The choice between concrete and asphalt is an age-old debate for pavement design. It is often a difficult decision to make, as both materials have their pros and cons when applied on driveways. Concrete offers durability while asphalt provides better traction and flexibility.

When debating which material would be best suited for one’s home it is important to consider the advantages of each option in order to determine the most suitable solution.

This article will discuss the benefits of concrete versus asphalt driveway options by comparing aspects such as cost effectiveness, longevity, maintenance requirements, environmental impact, aesthetics, safety features and more.

Furthermore, recommendations regarding the selection process will be provided so that readers can make informed decisions about which material suits them best.

Difference Between Asphalt And Concrete Driveways

Asphalt and concrete are both popular options for driveway construction; however, there are several key differences that must be taken into consideration when choosing the right material for a particular application.

Durability is an important factor to consider when evaluating the two materials; concrete is generally more durable and resistant to cracking in cold climates, while asphalt is more resistant to wear and tear.

Cost is also an important factor, with asphalt being generally cheaper although more prone to cracking, while concrete is more expensive but more durable.

Maintenance is also important, with asphalt requiring regular sealing and periodic repairs while concrete requires occasional sealing and minor repairs.

Ultimately, the choice between asphalt and concrete should be made based on a careful evaluation of the application, durability, cost and maintenance requirements.

Durability

The durability of asphalt driveways and concrete driveways is a key factor for homeowners to consider when deciding between the two materials.

Asphalt pavements are made up of a combination of aggregates, bitumen binders and additives which offer flexibility and strength under varying temperature conditions. On the other hand, concrete driveways are composed primarily of cement, water, sand, crushed stone or gravel and admixtures; resulting in higher compressive strength but asphalt is less resistance to temperatures fluctuations than asphalt paving.

When comparing the longevity of an asphalt driveway vs a concrete driveway, it is important to understand that both have different characteristics that can impact their overall lifespan.

Generally speaking, asphalt is considered more resistant to cracking due to its flexible properties while concrete may be more prone to cracks because it has poorer expansion qualities over time. Additionally, asphalt requires regular maintenance such as sealcoating every 3-5 years whereas no maintenance is required for a concrete driveway material unless repairs are needed after excessive wear and tear.

Both material types demonstrate excellent performance with regards to their ability to resist weather damage from freezing winter temperatures or hot summer days – this makes them ideal choices for any climate region.

Furthermore, since each pavement type is available in various colors and patterns they can match most home exterior styles without compromising on quality or durability attributes.

Given these factors into consideration, potential buyers must evaluate all options before selecting the best suited option based off personal preference and budget constraints as well as long-term needs like desired aesthetics or low maintenance requirements in order to secure a long-lasting driveway surface solution.

Cost

When discussing the cost of a new driveway, one must consider that asphalt driveways tend to cost less per square foot than concrete driveways. This is due to the fact that asphalt requires fewer materials such as cement and does not require additional labor for reinforcement or crack filling when compared to its concrete counterpart.

While an asphalt driveway will normally last about 20 years depending on weather conditions, a properly installed concrete driveway can last up to 30 years with proper maintenance. Therefore, while the initial installation costs of a concrete driveway may be higher than those of an asphalt driveway within the same area, in the long run it can be more economical due to its longer lifespan and decreased maintenance requirements over time.

Maintenance

The two most popular driveway options for homeowners are asphalt and concrete.

While initial installation costs of a concrete driveway may be higher, in the long run it can be more economical due to its longer lifespan and decreased maintenance requirements over time.

Proper maintenance is essential to ensure longevity of either type of driveway as both materials need regular upkeep such as sealing or resealing if necessary.

For an asphalt driveway, this includes making sure to patch any potholes that may arise and sealcoat every three years to protect from cracks caused by water damage.

Concrete driveways require cleaning with a power washer along with re-sealing every five years or so depending on usage.

Homeowners should consider these factors when deciding which material best fits their needs for a new driveway within their budget.

What Is Asphalt Driveway?

Asphalt driveways are composed of a variety of asphalt materials, typically asphalt cement, aggregate, and bitumen. Proper installation of asphalt driveways requires a foundation of compacted, stable soil and careful compaction of the asphalt layers. To ensure maximum longevity, asphalt driveways should be seal-coated every three to five years. Additionally, cracks should be filled as soon as they appear, and regular sweeping of dirt, sand, and debris should be done to prevent damage.

In areas with extreme weather, asphalt driveways may require additional maintenance, such as applying de-icing agents during the winter. In comparison to concrete driveways, asphalt driveways generally require less maintenance, making them a cost-effective, durable solution for many homeowners.

Asphalt Materials

Asphalt materials are a key component in asphalt driveways and come in many different forms. Asphalt cement, also known as bitumen, is the binding agent that holds the aggregates together and adheres them to an underlying layer of pavement. This material varies in consistency from solid to semi-solid form with a high viscosity. It has excellent adhesive properties which allow it to bond well with various substrates such as concrete or brickwork. Other asphalt materials include modified binders, mineral fillers, emulsions and cutback agents used for construction purposes.

Aggregates play a vital role in achieving desired performance characteristics of any asphalt surface. Aggregates can be natural gravels or crushed stones ranging from fine sand particles up to larger sized rocks and cobbles depending on the type of application and requirements of strength and durability needed by the driveway surface. The aggregate must be strong enough to withstand traffic loads while providing stability and skid resistance at the same time. A combination of both coarse and fine aggregates is often recommended for best overall results.

The installation process plays an important part in determining how long an asphalt driveway will last before needing maintenance or repairs. Proper compaction during construction is essential for ensuring that all layers are securely bonded together so they resist forces caused by heavy vehicles passing over them regularly without deforming or cracking prematurely under load stresses over time. Equipment such as rollers should be used after each lift or course of paving material is laid down to ensure adequate compaction levels have been achieved throughout the entire area being paved.

Quality control measures should also be taken into account when considering what type of driveway is better suited for your home; this includes checking grade elevations, drainage patterns, slope ratios, surfacing thicknesses etc., before approving any work done on site by contractors hired to install an asphalt driveway.

By following these guidelines one can ensure lasting longevity and quality performance out their newly installed asphalt driveway regardless if its residential use or commercial applications.

Asphalt Installation

Asphalt installation is an important step in creating a durable and long-lasting asphalt driveway.

Careful planning must be taken to ensure that the base layer of pavement, grade elevations, drainage patterns, slope ratios, surfacing thicknesses are all properly accounted for before any work begins onsite.

The correct compaction equipment such as rollers should be used to compact each layer of material during construction which helps secure bonding between layers and prevents premature cracking or deformation under load stresses over time.

Quality control measures should also be implemented throughout the entire process from start to finish in order to guarantee that the highest standard of quality has been met for a successful asphalt installation.

Asphalt Maintenance

Once the asphalt has been installed, proper maintenance is necessary in order to ensure its longevity and performance. Asphalt should be inspected regularly for signs of cracking or other damages that can lead to further deterioration if left unchecked. Any cracks should be filled with a rubberized sealant as soon as possible before any water damage occurs which could weaken the structural integrity of the pavement. Additionally, regular cleaning and sweeping of debris away from the surface helps prevent contaminants from settling into the asphalt and degrading it over time.

Oil spills should also be removed immediately using an absorbent material such as kitty litter or sawdust followed by a thorough rinse off with warm soapy water and a brush scrubbing motion. An annual professional sealcoating treatment will help protect against oxidation caused by UV light exposure while keeping the driveways appearance looking new.

Properly maintaining an asphalt driveway requires diligence but ensures long-term durability and satisfaction for years to come.

What Is Concrete Driveway?

Concrete driveways are a popular choice for surface pavements due to their durability, longevity, and low maintenance requirements. The primary advantages of concrete driveways include their resistance to cracking and their ability to withstand extreme temperatures.

However, the primary disadvantages of concrete driveways are their high initial installation costs and the fact that they require frequent resealing. Comparing concrete and asphalt driveways, concrete offers a longer lifespan, but asphalt is usually more cost-effective in the short term.

Advantages Of Concrete Driveways

Concrete driveways have become increasingly popular due to their durability, aesthetic appeal and low maintenance requirements. As a civil engineer specializing in pavement design, one can identify the advantages that concrete driveways offer for home owners.

Firstly, concrete is typically more durable than asphalt when it comes to crack resistance as well as being more resistant to damage from water or salt seepage. It also does not need frequent resurfacing which makes it an ideal choice if you are looking for a driveway with long-term performance potential.

Secondly, concrete driveways often look great and come in a variety of colors and designs making them highly customizable depending on your preference.

Thirdly, they do not require much maintenance apart from sealing every few years; this cost savings can be quite significant compared to other materials such as asphalt.

Finally, concrete is environmentally friendly since it requires far fewer resources during manufacturing than its alternatives while being recyclable at the end of its life cycle.

Thus, by considering all these factors there are clear benefits associated with using concrete as a driveway material over other options available today.

Disadvantages Of Concrete Driveways

Despite the many advantages of concrete driveways, there are some drawbacks that should be considered. These include a higher initial cost compared to alternatives such as asphalt due to the need for more materials and labor during installation.

Additionally, if driveway installed was not properly done, then cracks can appear over time which may require costly repairs or replacements in order to maintain its original look.

Furthermore, minor imperfections like air bubbles and color variations may also occur but these typically do not affect structural integrity.

Lastly, it is important to remember that concrete is a porous material so sealing must be done annually in order to prevent staining from oil or other liquids.

Consequently, civil engineers specializing in pavement design must ensure their clients understand all potential disadvantages associated with concrete driveways before making a decision on what type of driveway they wish to install.

Lifespan Of Concrete And Asphalt: Comparing Durable Material

- Asphalt and concrete driveways both require routine maintenance to prevent cracking and deterioration from exposure to the elements.

- Asphalt is known to be more resistant to extreme weather conditions than concrete and may require less frequent maintenance due to its higher durability.

- Concrete, however, is not easily affected by temperature fluctuations and the maintenance requirements for both materials are similar.

- Cost-effectiveness is a major factor when considering asphalt or concrete for a driveway; asphalt is typically cheaper than concrete.

- Over time, asphalt may become more expensive in terms of maintenance and repairs, while concrete is often seen as a more cost-effective option in the long run.

- Ultimately, the choice between concrete vs asphalt driveways depends on the homeowner’s budget, needs, and preferences.

Maintenance

The durability of a driveway can be greatly impacted by the amount of maintenance that it requires. In order to maintain an asphalt driveway, periodic resealing should occur every three years or so. This is due to oxidation from UV rays and weathering which leads to cracking. Additionally, weeds may grow in small cracks if left untreated.

Concrete driveways require less regular maintenance than asphalt but still need occasional repairs when exposed to freeze-thaw cycles. Cracks caused by these cycles can also become sites for weed growth if not addressed promptly with repair techniques such as crack filling.

Both concrete and asphalt driveways benefit from regular cleaning, usually involving sweeping away debris and using a pressure washer for heavier dirt buildup. It is important to use an appropriate cleaner depending on the type of material used; some cleaners are designed exclusively for either concrete or asphalt surfaces while others are suitable for both materials.

In terms of cost associated with maintaining each type of driveway over time, the initial installation cost of a concrete driveway is often higher than its asphalt counterpart and tends to last longer without needing major repairs; however, it does require more frequent sealing treatments despite requiring fewer minor repairs overall.

Asphalt driveways tend to have lower upfront costs and potentially shorter lifespans compared to concrete, although they generally do not require sealcoating treatments quite as often as their concrete counterparts do.

When making decisions about what type of driveway best suits one’s home needs, factors such as climate conditions, budget constraints, desired lifespan and available space must all be taken into consideration in order to make an informed choice between concrete versus asphalt options.

Weather Resistance

Weather resistance is an important factor to consider when determining the lifespan of a driveway. Asphalt driveways are more resistant to temperature fluctuations and freeze-thaw cycles than concrete, making them less likely to crack in cold climates. However, asphalt will eventually degrade due to UV exposure and require regular sealcoating treatments for protection from oxidation.

On the other hand, concrete driveways tend to hold up better against extreme temperatures but may experience more frequent cracking during warm weather months as well as surface scaling due to improper curing techniques or long periods without proper maintenance treatments. Both materials should be protected with sealers designed specifically for their composition in order to prevent further damage caused by environmental elements over time.

In order to maximize the longevity of one’s driveway while minimizing costs associated with repairs and maintenance, it is vital that appropriate construction methods be employed based on local climate conditions along with periodic inspections and maintenance checks throughout its lifetime.

Cost-Effectiveness

When attempting to evaluate the cost-effectiveness of asphalt and concrete driveway costs, a number of factors must be taken into account.

Initial costs for both materials can vary significantly depending on the size of the driveway area as well as other environmental considerations such as drainage or grading requirements. Asphalt tends to be less expensive in comparison, but may require more frequent maintenance treatments due to its susceptibility to UV damage over time.

Concrete driveways tend to have higher upfront costs but may offer greater value in the long run since they are more resistant to extreme temperatures and therefore less likely to experience cracking during freeze-thaw cycles or hot summers.

Furthermore, if proper curing techniques are employed along with periodic inspections and maintenance checks throughout its lifetime, it is possible that a concrete driveway could last up to three times longer than an asphalt one without requiring major repairs.

Therefore, it is important for engineers designing pavement structures to take these factors into consideration when making cost/benefit analyses for their projects.

Advantages Of An Asphalt Repair

Driveways paved with asphalt are known for their durability even when exposed to extreme weather conditions.

Studies have shown that asphalt driveways exhibit up to three times the lifespan of concrete driveways, making them a cost-effective investment in the long run.

Asphalt is also a low-maintenance material that requires minimal upkeep for long-term use.

Furthermore, asphalt can be kept in good condition through routine cleaning and sealing, which can also help prevent damage from chemicals, oil, gas, and other substances.

Additionally, a new asphalt driveway can be easily repaired by applying a new layer of asphalt, while concrete driveways require more involved and costly repair methods.

Finally, driveways paved with asphalt can easily be resurfaced over the years with a fresh layer of asphalt to maintain the aesthetic quality of the driveway.

Durability

The durability of driveways paved with asphalt is a key factor for evaluating the suitability of such pavements for residential applications. Asphalt is made up of bitumen, an oily, sticky and highly durable material that binds together sand and stone aggregate in order to form a strong pavement surface. This makes it ideal for enduring harsh weather conditions and heavy vehicular traffic without suffering any significant damage over time.

Moreover, properly constructed asphalt driveways can last anywhere from 20-30 years with minimal maintenance requirements if they are regularly sealed on a periodic basis. In addition, asphalt pavements have excellent resistance to freeze-thaw cycles which occurs due to temperature fluctuations during winter months. The flexibility of the material allows it to withstand cracking or crumbling when exposed to extreme temperatures while also exhibiting superior skid resistant characteristics compared to concrete surfaces.

Furthermore, modern methods of construction involve using layers upon layers of hot mix asphalt (HMA) materials along with additives in order to create impermeable shells that effectively prevent water intrusion into the underlying sub grade soils thus enhancing the overall longevity of an asphalt driveway. As far as asphalt repair work is concerned, potholes and cracks caused by wear and tear can be easily filled with cold patch materials whereas larger areas require resurfacing with HMA mixtures in order to restore its original strength.

In comparison, cracked or damaged concrete may need complete replacement instead which involves additional cost and effort than simply repairing an asphalt driveway. All these factors make asphalt paving a cost effective solution for long lasting performance at home sites. Overall, one can conclude that asphalt offers unparalleled durability when compared against other alternatives available making it well suited for residential use where maintaining aesthetic appeal alongwith longevity of the driveway is essential for homeowners.

Cost-Effectiveness

The cost-effectiveness of asphalt driveways is another key advantage when compared with other paving solutions.

Asphalt pavements typically require less maintenance and fewer repairs than concrete surfaces, making them a more economical option in the long run. It is less expensive than concrete.

Furthermore, installation costs tend to be lower as well due to the fact that asphalt materials are easier to work with and quicker to lay down.

The availability of cold patch materials which can be used for repairing minor cracks or potholes also help reduce the overall expenditure associated with asphalt pavements.

In comparison, concrete may need replacement rather than repair which makes it much more expensive to maintain over time.

Additionally, modern construction techniques involve using various additives along with hot mix asphalt (HMA) mixtures in order to provide further protection against water infiltration from rain or melting snow thus improving its longevity even under extreme weather conditions.

Ultimately, these factors make asphalt an affordable solution for residential use where both performance and budget constraints have to be taken into consideration while selecting a driveway material.

Low Maintenance

In addition to its cost-effectiveness, asphalt driveways offer many other advantages that make them the material of choice for paving residential surfaces.

One of the major benefits is their low maintenance requirements and long lifespan.

Asphalt pavements are designed to be durable and resistant to wear and tear under normal circumstances; this means that they typically need minimal upkeep over time.

Moreover, modern construction techniques involve adding various additives along with hot mix asphalt (HMA) mixtures which help reduce damage due to water infiltration as well as extreme weather conditions such as snow or hail storms. This factor ensures improved longevity and performance even in harsh climates.

In contrast, concrete may require more frequent repairs or replacement depending on how it has been installed and maintained.

Furthermore, any repair jobs can be done quickly using cold patch materials rather than having to replace entire sections of pavement which makes asphalt a great option from an economic standpoint as well.

All these features combined make it an ideal solution when selecting a driveway material for residential properties where both durability and budget matter.

Disadvantages Of An Asphalt Repair

Asphalt driveways typically require more frequent maintenance than concrete driveways to ensure the surface remains intact and free of cracks.

Asphalt driveways also tend to cost more initially than concrete driveways due to the nature of the material and the labor costs associated with installation.

Furthermore, asphalt driveways will typically require resealing driveway every few years, which can add to the overall cost of upkeep.

Finally, asphalt driveways tend to be more susceptible to damage from the elements, such as heavy rains, snow, and freezing temperatures.

Cost

The cost of an asphalt driveway is typically lower than that of a concrete driveway, making it an attractive choice for many homeowners.

However, the long-term costs associated with asphalt driveways should not be ignored.

The main disadvantage of an asphalt driveway is its shorter lifespan compared to a concrete driveway.

Asphalt has a life expectancy of around 15 years before it needs to be resurfaced or replaced, while a properly constructed and maintained concrete driveway may last up to 25 years or more.

Furthermore, resurfacing or replacing an asphalt driveway can be expensive due to the labor intensive process required in removing and disposing existing pavement material as well as preparing the subgrade prior to laying new material.

Additionally, cracks will develop over time due to thermal expansion and contraction during freeze-thaw cycles and are difficult if not impossible to repair without completely dig out and replace the damaged section.

This makes regular maintenance such as sealing essential in order prevent damage from occurring in the first place.

In summary, although asphalt driveways have some advantages related to initial cost, their significantly reduced service life make them less desirable when considering total lifecycle costs.

Maintenance

Maintenance is a critical component of any asphalt driveway. To ensure the longest possible lifespan, it is important to perform regular maintenance such as sealing and crack filling.

Sealing helps prevent water from penetrating the pavement which can lead to cracking and potholes over time. Crack filling also helps reduce further damage by preventing water intrusion into the subgrade beneath the asphalt layer.

Additionally, sealcoating may be necessary every three years or so in order to protect the surface from oxidation caused by ultraviolet radiation and other environmental factors. All these activities should be performed by a qualified professional in order to maximize its effectiveness and extend service life.

In short, proper maintenance is essential for preserving an asphalt driveway’s integrity throughout its service life.

Advantages Of A Concrete Repair

The durability of concrete driveways is superior to asphalt driveways due to its composition and strength.

Concrete driveways require minimal maintenance, such as sealing every 1-3 years, and can last up to 30 years.

The cost-effectiveness of concrete driveways is another advantage, as they tend to have a lower installation cost than asphalt driveways and are more resistant to damage.

They also require less frequent resurfacing or repairs due to their superior durability.

Concrete driveways are an economical solution, as they are more resistant to cracking and sinking, and require less maintenance over the long-term.

With the right maintenance plan, a well-installed concrete driveway can last a lifetime.

Durability

The durability of a driveway is an important factor in deciding which type to install.

Concrete driveways are known for their longevity and sustainability, with many lasting more than 20 years when properly maintained. In comparison to asphalt driveways, concrete can withstand higher levels of traffic and exposure to the elements due to its strength and resistance from wear and tear.

This makes it ideal for longer-term use as the initial cost may seem high but over time, concrete has been proven to be more affordable since fewer repairs, replacements or maintenance procedures will need to be carried out throughout its lifetime.

Furthermore, concrete does not require regular sealcoating like asphalt does as it naturally prevents water penetration and requires less frequent resurfacing compared to other materials such as gravel.

Therefore, this makes it a desirable option for those who want long term value without having to invest in additional costs on a regular basis. Ultimately, by selecting concrete one can enjoy greater peace of mind knowing that they have chosen a material that offers superior reliability and performance at minimal costs over the lifespan of the driveway.

Maintenance

Due to its strength and resistance from wear and tear, maintenance of a concrete driveway is relatively low in comparison to other materials.

In general, it does not require regular sealcoating like asphalt does as it naturally prevents water penetration.

Furthermore, the material itself is generally more resilient than others such as gravel or dirt which means that fewer repairs need to be conducted throughout its lifetime.

Resurfacing may also be required less frequently as long as proper precautions are taken when installing the concrete. For instance, applying an appropriate sealer can extend the life of the surface by preventing damage from weathering due to exposure to sun and rain.

Additionally, cracks should be filled promptly with a high-grade filler material in order for them not to worsen over time.

Overall, these steps along with regular sweeping and cleaning will help ensure that the driveway remains durable while still preserving its aesthetic appeal.

Cost-Effectiveness

When considering the advantages of a concrete driveway, cost-effectiveness is an important factor to consider. As with any material used for construction purposes, installation costs are typically higher for concrete than other materials such as asphalt or gravel.

However, in terms of long-term maintenance and repair costs, concrete is more economical. In addition to being highly resistant to wear and tear and not requiring regular sealcoating like asphalt does, it also requires fewer repairs throughout its lifetime due to its resilience.

Furthermore, properly installed concrete can last decades without needing resurfacing if maintained correctly which helps keep overall upkeep costs down. This makes it an ideal choice for those looking for a durable yet affordable solution for their driveways that will stand up to changing weather conditions over time.

Disadvantages Of A Concrete Repair

The initial cost for a concrete driveway is more than that of an asphalt driveway.

Furthermore, a concrete driveway requires more maintenance due to its susceptibility to wear and tear from the elements. This can include the need for sealing and resealing, as well as regular cleaning.

One of the most common problems with a concrete driveway is cracking, which can be caused by a variety of reasons such as poor construction, thermal expansion and contraction, or the presence of water. Cracks need to be filled to prevent further damage and to maintain the structural integrity of the driveway.

Overall, a concrete driveway is more expensive, requires more maintenance, and is more likely to crack than an asphalt driveway.

Expense

The cost of a concrete driveway is one factor that must be taken into consideration when deciding if it is the best choice for a particular situation. Depending on the size and complexity, installing a new concrete driveway can range from relatively inexpensive to very expensive.

The expense of pouring a large amount of concrete will depend on the availability of materials, labor costs and other variables such as excavation, grading or drainage requirements. Furthermore, due to its weight and rigidity, special considerations may need to be made in order to properly support the slab without creating excessive stress on existing structures.

Additionally, repairs are often labor intensive and costly since they typically require cutting out sections of damaged material and replacing them with fresh pour. In comparison, asphalt driveways tend to have lower installation costs than those associated with poured concrete slabs since only minimal preparation is required prior to laying down the pavement layer.

Maintenance

The maintenance of a concrete driveway is another important factor to consider when evaluating the overall cost and upkeep associated with this type of pavement.

Regular sealcoating, patching, and crack filling will extend the lifespan of a concrete driveway but these activities can be labor intensive and costly.

In addition to these tasks, any efflorescence that appears on the surface should also be addressed as soon as possible in order to prevent further degradation.

Furthermore, due to its weight and rigidity, it is essential that all underlying support structures are regularly inspected for stability and signs of settling or shifting before additional material is applied on top of them.

As such, regular inspection by an experienced civil engineer is recommended in order ensure long-term performance of the structure.

Cracking

Cracking is a common problem associated with concrete driveways and can be caused by several factors such as temperature changes, ground settlement, poor installation practices, or inadequate subgrade support.

If left untreated, cracks can lead to further deterioration of the pavement structure due to water infiltration which could result in additional cracking and costly repairs.

Depending on the severity of the damage, crack repair may involve anything from sealing small hairline fractures to replacing large sections of damaged material.

In order to prevent these issues from arising prematurely it is important for designers and contractors to consider all possible causes before commencing construction.

For example, adequate drainage systems should be installed during initial design stage as well as providing sufficient reinforcement beneath the driveway surface where applicable.

Proper maintenance also plays an essential role in prolonging the life expectancy of a concrete driveway; regular patching and seal coating will help protect against moisture penetration into cracks while minimizing other types of damage caused by wear and tear over time.

Pros And Cons To Consider When Deciding What Materials To Choose

When deciding between concrete and asphalt for a driveway, the cost of installation and maintenance should be taken into account.

Durability, climate, and maintenance requirements are all important factors to consider.

The aesthetics, drainage, and accessibility of the driveway should also be taken into account.

Noise, safety, environmental impact, and space should also be considered.

Additionally, legal restrictions, resale value, traction, and allergens should be considered.

Ultimately, all of these factors should be taken into account for an informed decision.

Cost

When considering the cost of a driveway, concrete and asphalt are both viable options. Concrete can be slightly more expensive upfront due to the materials used, however it is known to last much longer than asphalt so in the long run may prove to be less costly.

Asphalt is cheaper initially but will need repairs over time as its surface wears away quickly if not properly maintained. It also requires seal coating every few years which adds additional costs that must be considered when budgeting for a new driveway installation.

Therefore, depending on the amount of money available, either option could be suitable for a homeowner’s needs. When evaluating these materials further, it is important to take into account factors such as climate conditions where they will be installed since certain locations may have different requirements for each material based on their local environment.

Additionally, visual aesthetics should also factor into the decision making process; one type of paving material might look better than another depending on individual preferences or even city regulations in some cases.

Both concrete and asphalt provide many benefits regardless of location and while there are differences between them in terms of pricing and longevity, an informed choice can help ensure that a property owner gets exactly what they want out of their project.

Durability

Durability is an important factor when deciding between asphalt and concrete for driveway installation.

Concrete is known to be more durable than asphalt, with the lifespan of a properly constructed concrete driveway lasting up to 30 years or longer.

Asphalt has a shorter lifespan, typically around 15-20 years if it is well maintained and receives regular seal coating.

Despite its lower cost upfront, asphalt may not prove to be as cost effective in the long run due to its rapid deterioration over time compared to concrete’s improved longevity.

Temperature fluctuations can also affect the durability of either material; cold climates are better suited for concrete whereas hot climates tend to favor asphalt paving due to its flexibility and ability to expand without cracking under extreme temperatures.

Civil engineers should consider these factors carefully before selecting a pavement material for any given project in order to ensure that their customers get adequate value from their investment.

Maintenance

Maintenance is an important factor to consider when deciding between asphalt and concrete for driveway installation. The type of maintenance required can vary depending on the material chosen, as well as local climate conditions and usage.

Concrete driveways require regular sealing every two to three years in order to retain their strength and durability; failure to properly seal a concrete driveway will result in cracking or chipping over time due to water infiltration.

Asphalt requires less frequent maintenance such as patching minor cracks, resealing every four to five years, and periodic sweeping or cleaning with mild detergents.

Additionally, proper drainage should be factored into any pavement design plan in order to ensure that surface runoff does not cause further damage to the paving material over time.

Civil engineers must take all these considerations into account when choosing a suitable construction material for a given project site.

Comparing Maintenance Requirements

The cost of maintenance for asphalt driveways is typically lower than that of concrete driveways as asphalt surfaces require less frequent repairs and can be resurfaced at a cheaper cost.

Asphalt driveways typically require resurfacing every 3-5 years, while concrete driveways tend to require maintenance or replacement every 20-30 years.

Cleaning requirements for asphalt driveways are relatively simple, and the surface can typically be cleaned with a broom and water.

For concrete driveways, more intensive cleaning may be required, such as pressure washing or scrubbing with a wire brush.

Cost Of Maintenance

The cost of maintenance is an important factor when considering the choice between a concrete or asphalt driveway.

Concrete driveways require more upfront costs to install, but may last up to 30 years with minimal upkeep compared to 20-25 years for asphalt surfaces that need frequent repairs and seal coating.

Maintenance of concrete involves occasional cleaning and sealing every few years; repair usually requires replacing sections only if there are cracks or significant damage due to weathering.

Asphalt driveways typically require regular resealing every 3-5 years which can improve its durability and performance over time.

Repairs on asphalt involve filling potholes, repairing ruts and cracks in order to extend the life of the pavement surface.

Overall, both concrete and asphalt offer low cost options for installation and periodic maintenance when compared to other materials such as brick pavers.

However, since they are susceptible to wear and tear from vehicle traffic, harsh climates, freeze/thaw cycles, deicing salts, oil spills etc., it’s recommended that their condition be monitored regularly in order to minimize costly repairs down the road.

Regardless of the material chosen for a driveway project, having proper drainage systems installed during construction will go a long way towards prolonging its lifespan while minimizing ongoing expenses associated with maintenance.

Frequency Of Maintenance

Frequency of maintenance is an important factor to consider when deciding between a concrete or asphalt driveway.

Depending on the climate and usage, some surfaces may require more frequent upkeep than others.

For instance, in climates that experience harsh winters with frequent freeze/thaw cycles, asphalt will need to be sealed more often due to its susceptibility to cracking and potholes.

Concrete also requires sealing every few years but can typically go several years before needing significant repairs compared to asphalt driveways.

Regular inspections should always be conducted as part of any preventive maintenance plan for both materials so that any signs of deterioration are addressed promptly.

In addition, proactive steps such as using deicing salts sparingly during winter months will help reduce long-term costs associated with repair and replacement of either type of pavement surface.

Cleaning Requirements

In addition to the frequency of maintenance, cleaning requirements must also be taken into consideration when deciding between a concrete or asphalt driveway.

Asphalt driveways can sometimes require more frequent cleaning than their concrete counterparts due to oil and grease that may have been spilled on them.

Concrete surfaces are generally easier to clean since they do not absorb stains as easily; however, deeper stains still need special attention in order for them to be removed effectively.

In either case, regular sweeping should always be part of any preventative maintenance plan so that debris does not accumulate and cause damage over time.

Specialized cleaners may also be necessary for removing tough stains such as those caused by petroleum products or other automotive fluids.

Pressure washing is recommended for both types of pavement surface but extra care must be taken with asphalt because high-pressure water jets can damage it if used improperly.

Homeowner Tips For Maximum Pave Longevity

The proper installation of a concrete or asphalt driveway is essential for maximizing its longevity.

For concrete, the base must be adequately prepared to ensure proper drainage and prevent cracking.

Asphalt requires a stable and well-draining base, as well as a seal coat every two to three years.

Regular maintenance is key to maximize the life of either material, such as properly filling cracks, cleaning, and using a sealant for asphalt.

Proper Installation

The proper installation of a driveway is essential for both concrete and asphalt driveways. In order to maximize longevity, the subgrade should be properly compacted before installing either type of surface. Poor compaction can lead to erosion or settling in the future, leading to cracking and other issues that reduce the lifespan of your driveway.

To ensure that this does not happen, it is important to prepare your driveway with an adequate thickness of gravel base material on top of the compacted soil. The amount of gravel needed depends on the intended use; for instance heavier vehicles require thicker layers than lighter ones. Additionally, if there are any steep grades present they must be taken into consideration when constructing the driveway as these will affect drainage patterns and may create puddles or wet spots in areas where water sits for too long.

It is also important to note that when installing an asphalt surface, compaction must take place immediately after laying each layer down while still hot. Lastly, any edges should be sealed against water infiltration which can cause further damage over time. With proper installation practices adhered to, both concrete and asphalt driveways have great potential for achieving maximum longevity.

Maintenance Routine

Once a driveway is installed, proper maintenance must be taken to ensure maximum longevity.

Regular inspections should take place every 3-4 months for signs of wear and tear such as cracking or potholes. If any issues are found they should be addressed promptly in order to prevent further damage.

The pavement surface must also regularly be kept clean by removing debris and sweeping away dirt and dust which can accumulate over time if left unchecked.

Additionally, sealcoating asphalt surfaces on an annual basis will protect against UV rays, water infiltration, oxidation, and other environmental factors that contribute to deterioration.

Furthermore, regular edging with either concrete or asphalt edges helps maintain the shape of the driveway and reduce erosion from wind or rain runoff.

All these practices combined help keep driveways looking great and lasting as long as possible.

What Is Cheaper: Asphalt Or Concrete Driveway?

When considering the cost of materials for asphalt or concrete driveways, asphalt is typically cheaper due to the fact that it is a much simpler material to work with.

However, the labor costs associated with asphalt may be higher due to the additional steps required in the installation process.

On the other hand, concrete may require more materials but can be laid in fewer steps, so labor costs are often lower.

Overall, the cost of a driveway will depend on the specific driveway design and the type of material chosen.

Cost Of Materials

When it comes to the cost of materials, asphalt and concrete are two choices that must be considered when selecting a driveway material.

Asphalt is generally cheaper than concrete upfront because less raw material is needed for its installation. However, it requires more frequent maintenance due to its short lifespan and may not last as long in comparison with concrete.

Comparatively, concrete has higher initial costs but will require fewer repairs or replacements over time making it an economical option in the long run.

The type of aggregate used plays a major role in determining the price per ton of both asphalt and concrete. For instance, limestone-based aggregates such as sandstone have low production costs which makes them an ideal choice for asphalt while more expensive granite-based aggregates are better suited for producing high strength and durable concrete mixes. Furthermore, factors like transportation distance from quarrying sites can affect the overall cost of materials significantly.

In addition to purchasing costs, other expenses related to construction such as labor charges should also be taken into account before deciding on a driveway material.

Both asphalt and concrete need special equipment such as rollers or mixers that are operated by professional contractors who charge based on their experience level and expertise in handling specific tasks involved in laying down either surface course.

Thus, careful consideration should be given towards these associated costs before choosing one particular material over another.

Overall, while there is no definitive answer regarding which pavement type provides greater value in terms of cost efficiency between asphalt and concrete driveways; it is important to consider all relevant aspects including material selection criteria, pricing structure along with labour charges before arriving at any final decision so that a suitable solution can be identified according to individual requirements.

Labor Costs

When it comes to labor costs, asphalt and concrete require different installation techniques that are handled by professional contractors.

Asphalt requires more intensive preparation work and thus the cost of laying down a new driveway is higher than that of concrete.

On the other hand, concrete takes longer to install due to its curing time but usually involves fewer steps in the paving process resulting in lower labour charges overall.

The equipment and machinery needed for either material also differ greatly with rollers being primarily used for asphalt while mixers or vibrators are necessary for working with concrete.

Furthermore, skilled workers who specialize in pavement design may be required depending on the complexity of the job at hand and their rates can vary significantly from one region to another.

In conclusion, evaluating all associated expenses including labour costs will provide an accurate estimate of what option presents better value when selecting between asphalt and concrete driveways.

Conclusion to Asphalt vs Concrete Driveway

The comparison between asphalt and concrete driveways is an important decision for any homeowner. Both materials have advantages and disadvantages, which should be taken into consideration when making the final selection.

It is essential to understand that choosing the right material can extend driveway life expectancy significantly. On average, properly maintained concrete driveways last up to 30 years while asphalt may need replacing every 10-15 years depending on climate and installation quality.

When deciding on a driveway material it is vital to consider all factors such as cost of initial installation, maintenance requirements, and local weather conditions. A carefully selected option will provide many years of satisfaction with minimal long term costs.

With some basic knowledge and careful planning, homeowners can ensure their investment in their home lasts for many years to come.